The V series is a vertical auger feeder that ranges in size from 7 to 16m³ with a single vertical auger.

The strength and quality of workmanship are easy to see on the V Series. An independent reinforced chassis and a single axle provide a solid base for the feeder body. There are many tyre options to vary the loading or feed-out height. The independent chassis features 4 x Dinamica Generale weigh-cells as standard, one on each corner, and these weigh-cells provide a highly accurate indicator of feed weight.

V-Series – Single Auger

| Product | Wheels | Door | 2 Speed | Axle |

|---|---|---|---|---|

| V7 | 30 x 11.5 R14.5 | 1 | No | single |

| V10 | 435/50 – R19.5 | 1 | No | single |

| V12 | 435/50 – R19.5 | 1 | No | single |

| V14 | 435/50 – R19.5 | 1 | Yes | single |

| V16 | 435/50 – R19.5 | 1 | Yes | single |

The V series is a vertical auger feeder that ranges in size from 7 to 16m³ with a single vertical auger. The strength and quality of workmanship are easy to see on the V Series. An independent reinforced chassis and a single axle provide a solid base for the feeder body. There are many tyre options to vary the loading or feed-out height. The independent chassis features four Digi-Star weigh-cells as standard, one on each corner, and these weigh-cells provide a highly accurate indicator of feed weight.

Strength

Reinforcement to the underside of the floor helps to strengthen it from the vertical forces of feed being loaded into the machine. This feature and strength are unique to Hi-Spec. The V Series feeder body is made from eight-millimetre high-grade steel. The body is tapered to allow efficient mixing and also to maximise volume. The eight-millimetre body is very resistant to wear, and the top of the body is also tapered inwards, which helps to brace the feeder and retain the natural inherent strength. In addition, the top of the feeder is fitted with an over-flow ring to prevent spillage.

Gearboxes

Hi-Spec uses Comer gearboxes as standard across its vertical feeder range. Comer Industries is a global leader in designing and producing advanced power transmissions and gearboxes. Established in Italy at the beginning of the 1970s, Comer Industries has grown to become a major supplier to over 60 countries worldwide. A robust PGA planter-reducing gearbox is provided as standard for the auger rotation. The PGA gearboxes possess strong torque characteristics to ensure the mixers cope with chopping and mixing effortlessly. Each gearbox is supplied with an independent oil reservoir. Service and maintenance are quick and convenient through an inspection hatch located on the auger. Fitted on sizes greater than 12m³, the two-speed gearbox allows the auger to rotate at multiple speeds. The low-speed setting allows smaller HP tractors to operate the mixers and is also used for restarting after overnight settling. Operators can choose the high-speed setting to provide complete and rapid emptying of the mixer. The two-speed gearbox is an optional extra on sizes 12m³ and smaller.

Mixing

The V Series feeders use a central auger to perform the chopping and mixing functions. The auger does this in an effortless cycle of action. Firstly it draws the feed up the central flighting and then allows it to fall down the tapered sides to repeat the cycle. All the while, the auger is also rotating the feed around the body of the feeder. For chopping, the augers are fitted with self-sharpening blades. These blades are mounted on 15mm support plates for increased strength. The chopping blades are adjustable through three positions for increased or decreased cutting. In addition, two counter plates positioned on the feeder body hold the feed or bale in situ, allowing the rotating auger to chop the feed before mixing. The two counter plates are also adjustable for increased flexibility.

Load Weighing

Four Dinamica Generale weigh-cells as standard and a DG600 display provide an extremely accurate feed weight. In addition, the DG600 display comes with a faster micro-processor than previous models and an easy-to-read white back-light display.

The DG600 allows you to:

• Build several recipes for multiple pens.

• Choose one ingredient for 99 pens and 99 ingredients for one pen or any combination.

• Mixing time control.

• Compatible with the DTM Daily TMR Software

• Utilise basic recipe and batching capabilities.

Additional Features

The V Series feeders are fitted with the following features as standard:

• 540-1000rpm PTO drive

• Comer PGA gearbox

• 4 x Dinamica Generale weigh-cells

• Programmable DG600 readout display

• Reinforced 20mm floor

• 15mm auger flighting

• 8mm body thickness

• Adjustable serrated forage blades

• Auger kicker plate

• Adjustable counter plates

• Gearbox oil reservoir

• Viewing ladder

• Spillage ring

• Single feed-out door

• Adjustable feed-out chute

• Drawbar stand

• Parking brake

• Ring hitch

• Hydraulic brakes

• LED road lights (x1)

• Hi-Spec red paint finish

• Mudguards

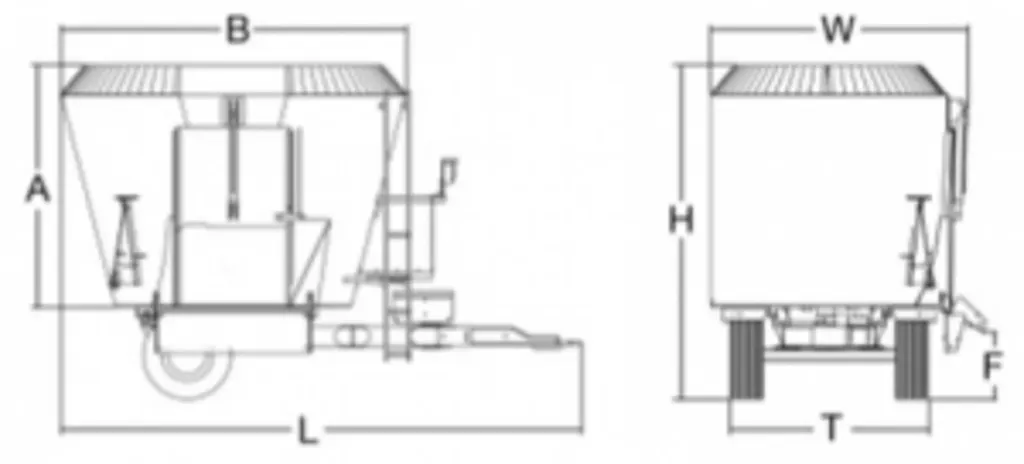

| Product | Mtrs | W | H | L | F | Weight |

|---|---|---|---|---|---|---|

| V7 | 7m³ | 2220 | 2610 | 4280 | 610 | 3600kgs |

| V10 | 10m³ | 2620 | 2960 | 5110 | 850 | 4700kgs |

| V12 | 12m³ | 2620 | 3120 | 5160 | 850 | 5000kgs |

| V14 | 14m³ | 3020 | 2960 | 5550 | 850 | 5900kgs |

| V16 | 16m³ | 3020 | 3160 | 5600 | 850 | 6400kgs |