Discover Our Range Of Hi-Spec Spreaders

XCEL Spreader

Discover Our Range Of Hi-Spec Spreaders

XCEL Spreader

The XCEL rear discharge spreader provides precision manure spreading management.

Our unique technology of the shredding rotor and spinning discs provides a precise manure application. The spreading width of the XCEL is 24 metres, based on the material. Its capacity is 12 tonnes, and the load can be spread in approximately 3 minutes.

XCEL Spreader Range

| Product | Wheels | Capacity | Spreading |

|---|---|---|---|

| 1250 XCEL | 580/70 R38 | 12 tonnes / 14.5m³ | 24 metres |

Our unique patented and proven chain and disc spreading achieves better consistency and much greater widths than a standard vertical auger spreader. The XCEL uses two high-strength marine chains to convey the manure towards the rear beater. This hydraulically driven floor with box iron slats provides a constant manure flow to the shredding rotor. Our unique rotor can handle a more comprehensive range of manures than vertical auger spreaders, so our unique rotor shreds and spreads manure more intensively to ensure a faster uptake in crop nutrition and a reduction in time to grazing.

Features

Shredding Rotor

Twenty-two heavy-duty marine chains and Hardox flail heads rotate over 220rpm to shred the manure intensively. A unique feature of our chain rotor is that it allows the passage of foreign objects through the rotor. Unfortunately, foreign objects are more likely to cause severe damage to fixed rotor spreaders. The enclosed Hardox hood over the rotor ensures that the manure is delivered directly to the spinning vanes. The high velocity and shredded nature of the manure ensure an even and consistent pattern over 24 metres. In addition, the Hardox hood is fitted with an adjustable canopy to place the manure onto the discs accurately.

Spreading:

The XCEL is packed with features to ensure it can cope with any spreading manure. To begin spreading, the wide-angle PTO is engaged at 1000rpm to drive the rear discs and rotor. A galvanised reinforced slurry door is set to the desired height depending on the material to be spread. The slurry door height is easily viewed with an indicator on the front of the spreader. It can be raised and lowered via a hydraulic spool as required. The two-floor chains and slatted floor convey the manure to the shredding rotor. The floor chains are manually tensioned from the front of the spreader. The double floor chain further eliminates the risk of bridging, as can occur with four-chain setups. The floor speed can also be hydraulically controlled from the cab.

The manure is shredded through the rotor and placed onto the spinning discs via the adjustable canopy. The large diameter spinning discs are rotated over 500rpm; this additional speed helps spread the manure over 24 metres. The vanes on the discs are also adjustable to allow varying spreading patterns depending on the material to be spread. The discs are driven via a single-piece gearbox. The precise gearbox casting allows perfect alignment of the driveline. All gearboxes are rated for 200HP.

Additional Features

• Ring hitch

• Parking brake

• Wide angle PTO

• Marine floor chains c/w manual tensioning

• Hydraulic floor drive

• Marine chain beater c/w Hardox flail heads

• Galvanised reinforced slurry door c/w height indicator

• Galvanised Hardox hood c/w adjustable canopy

• Spinning discs c/w adjustable vanes

• Central greasing to bearings

• Commercial axle c/w 420×180 hydraulic brakes

• 580/70 R38 tyres

• Automatic chain oiler

• LED road-lights

• Hi-Spec red paint finish

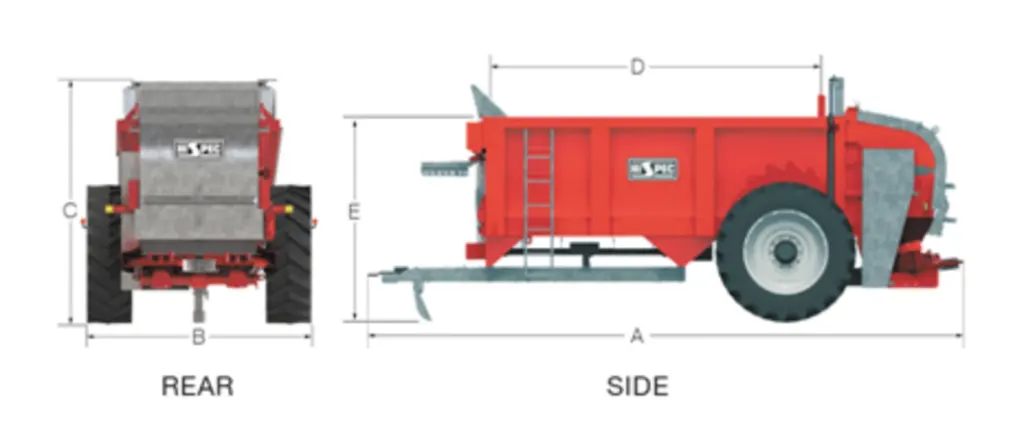

| Model | Tyres | Capacity | Length A | Width B | Height C | Body D | Loading L | Weight |

|---|---|---|---|---|---|---|---|---|

| tonne / m³ | mm | mm | mm | mm | mm | kg | ||

| 1250 XCEL | 580/70 R38 | 12 / 14.5m³ | 8300 | 3060 | 3085 | 4850 | 2450 | 6800 |